By: Greg Perruzzi

The construction industry is undergoing a significant transformation, driven by the adoption of emerging technologies that are reshaping traditional practices. These innovations are enhancing efficiency, safety, and collaboration across projects, leading to improved outcomes and substantial cost savings.

As the industry continues to embrace digital transformation, these technologies promise to redefine construction processes, making them more efficient, sustainable, and responsive to the demands of modern projects. The integration of these tools marks a new era in construction, where innovation leads to tangible improvements and sets the stage for future growth and development.

1. Building Information Modeling

Building information modeling (BIM) has become essential for project planning and coordination, offering 3D digital representations that integrate architectural, structural, and mechanical, electrical, and plumbing (MEP) data into a single model. Usage rates in the US now exceed 70% among contractors, engineers, and architects, facilitating more accurate clash detection and tighter cost controls.

While BIM offers numerous advantages, it also presents certain risks and challenges, including data security and privacy concerns due to the amount of information being shared, as well as a steep learning curve due to the complex nature of the systems.

Read more: Cyber Threats in Construction: 5 Key Vulnerabilities

2. IoT Sensors and Wearable Devices

The deployment of Internet of things (IoT) devices — ranging from environmental sensors to wearable safety monitors — enables real-time tracking of equipment usage, material conditions, and worker health metrics. Early adopters report up to a 30% reduction in on-site incidents and improved resource allocation through continuous data streams.

Challenges to the adoption of wearables and IoT devices in construction include data privacy, the initial cost of implementation, and the need for additional worker training.

Read more: Role of Wearables and the IoT in Enhancing Construction Site Safety.

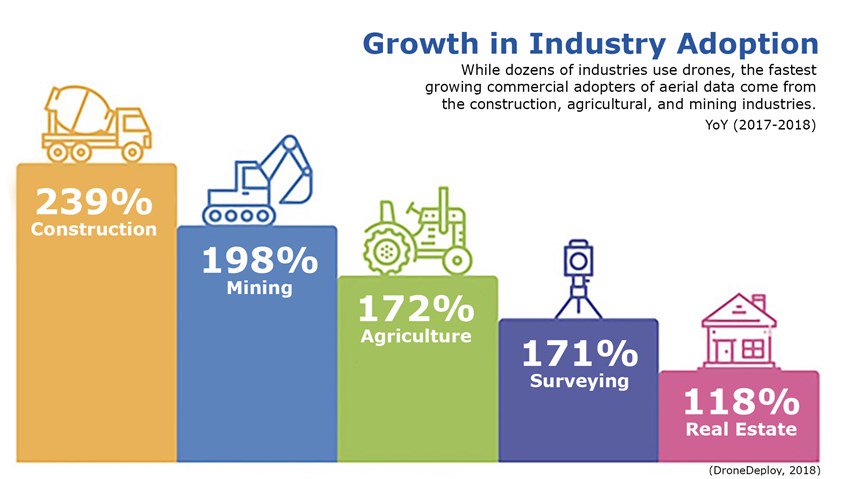

3. Drones

Unmanned aerial vehicles, or drones, have become indispensable for inspecting, surveying, and monitoring sites in the construction industry. Their usage has significantly helped reduce the estimated $160 billion in annual waste on construction sites. For instance, drones provide real-time stockpile measurements of building materials, improving measurement accuracy by 61%.

There's also growing optimism that drones can help reduce construction worker injuries and fatalities. With drones, construction companies can conduct surveys and inspections without endangering workers, which would lead to a 55% increase in safety standards.

While drones offer substantial benefits, they also present significant risks that could lead to expensive liability claims.

- Accidents and property damage: Drone malfunctions, such as collisions with structures or equipment, could cause property damage or even injuries. For example, a malfunctioning drone could crash into a building under construction, leading to expensive repairs or worker injuries that may result in liability claims.

- Privacy violations: Drones capturing images or videos of individuals without consent can lead to privacy infringement claims. In states such as Alabama, strict laws protect individuals from unauthorized drone surveillance. Thus, construction companies could face lawsuits or reputational damage.

- Federal Aviation Administration (FAA) certification: In the US, any commercial use of drones, including in construction, requires compliance with FAA regulations. Operators must obtain FAA Part 107 certification, which includes passing a knowledge test that covers topics such as airspace regulations, weather conditions, and safety protocols. This certification is mandatory for legal commercial drone operations and reduces risks by ensuring that drone pilots are knowledgeable and trained.

Construction companies must ensure that their drone operators are FAA-certified and adhere to all federal and local drone operation guidelines. Noncompliance could result in fines, operational delays, or even further liability in the event of an accident.

4. Robotics and Automated Machinery

Robotic solutions, such as bricklaying robots and automated rebar-tying machines, target repetitive tasks and reduce reliance on scarce skilled labor. Although only about 55% of firms currently use robotics, adoption is rapidly increasing as pilot programs demonstrate up to 50% gains in productivity and significant safety improvements.

While this advancement in technology helps solve the ongoing labor shortage and need for workers, it isn't without risk. In addition to high initial investments and the threat of technical failures and subsequent delays, malfunctions or improper use of machinery can pose dangers to workers onsite. Additional training and safety precautions must be implemented to help mitigate any risks posed to people onsite.

5. AI-Driven Predictive Analytics

AI-driven platforms analyze historical project data to forecast costs, schedule risks, and staffing needs. Predictive models can flag potential overruns weeks in advance and optimize bidding strategies, with users reporting up to a 20% reduction in budget variances.

However, predictive analytics rely on data quality and accuracy. Inaccurate or incomplete data can lead to flawed predictions, impacting project outcomes and decision-making. Over-reliance on this technology can also be risky; it should be used as a support tool rather than a replacement for expert judgment and experience.

Measurable Benefits of Construction Technology

According to a McKinsey Global Institute report, digital transformation in construction can yield productivity gains of 14-15% and cost reductions of 4-6%.1 These measurable improvements demonstrate that investing in technology delivers concrete returns — not just hype. The following benefits illustrate how digital tools are reshaping project outcomes:

1. Productivity Gains and Throughput Boosts

Technology-driven workflows — from radio-frequency identification (RFID)-enabled material tracking to connected site platforms — can enhance labor productivity by 30-45% in field operations, while integrated project management tools reduce rework and delays for faster project delivery.

2. Enhanced Safety and Risk Mitigation

Real-time IoT sensor networks and wearable devices enable continuous monitoring of environmental conditions and worker vitals, leading to a reported 30% reduction in on-site incidents and more efficient hazard response protocols. Automated alerts and data analytics streamline incident investigations, ensuring compliance and fostering a stronger safety culture.

3. Waste Reduction and Predictive Maintenance Savings

Predictive maintenance systems analyze equipment performance data to forecast failures, cutting maintenance costs by 18-30% and reducing downtime by up to 45%. Simultaneously, digital material optimization tools minimize inventory waste and over-ordering, delivering substantial savings on high-value components such as steel and concrete.

4. Cloud-Based Collaboration Improvements

Cloud solutions centralize project data — drawings, schedules, requests for information (RFIs) — in a single, accessible repository. Gartner predicts that over 70% of construction firms will adopt industry-specific cloud platforms by 2027, enabling real-time coordination across offices and job sites, reducing miscommunication, and accelerating decision-making.2

Automation Risks in Construction

Automation in the construction industry offers numerous benefits, including increased efficiency, reduced labor costs, and enhanced precision. However, it also introduces several risks that need to be carefully managed. The integration of advanced technologies can expose construction projects to cybersecurity threats, where malicious attacks could disrupt operations or compromise sensitive data. There's also the risk of equipment malfunction or failure, which can lead to project delays, increased costs, and on-site safety hazards.

To mitigate these risks, it's crucial for construction companies to implement comprehensive risk management strategies, such as regular system audits, employee training programs, and robust cybersecurity measures. By addressing these challenges proactively, the construction industry can harness the benefits of automation while minimizing potential downsides.

In conclusion, while the adoption of emerging technology in construction enhances efficiency, it also introduces new risks. By addressing challenges proactively, the construction industry can benefit from technological advancements while safeguarding operations and financial stability.

To learn more about Gallagher Bassett's partnered approach for the construction industry, visit our construction industry solutions page.

Author

Sources

DroneDeploy. (2018, June 7). The Rise of Drones in Construction. www.dronedeploy.com/blog/rise-drones-construction/

Doyon, Dan. 2024. "AI Construction Safety in a Changing World: Adapt and Innovate." ASA Foundation, June 25. fasacares.org/ai-construction-safety-in-a-changing-world-adapt-and-innovate/

Make Gallagher Bassett your dependable partner

When making the right decision at the right time is critical to minimize risk for your business, count on Gallagher Bassett's extensive experience and global network to deliver.